CONDUIT HAS RAISED A $4.7M PRE-SEED

Our Interoperable Orchestration Platform (IOP) delivers

factory-wide AI automation in days, not months.

OUR PLATFORM

OUR PROCESS

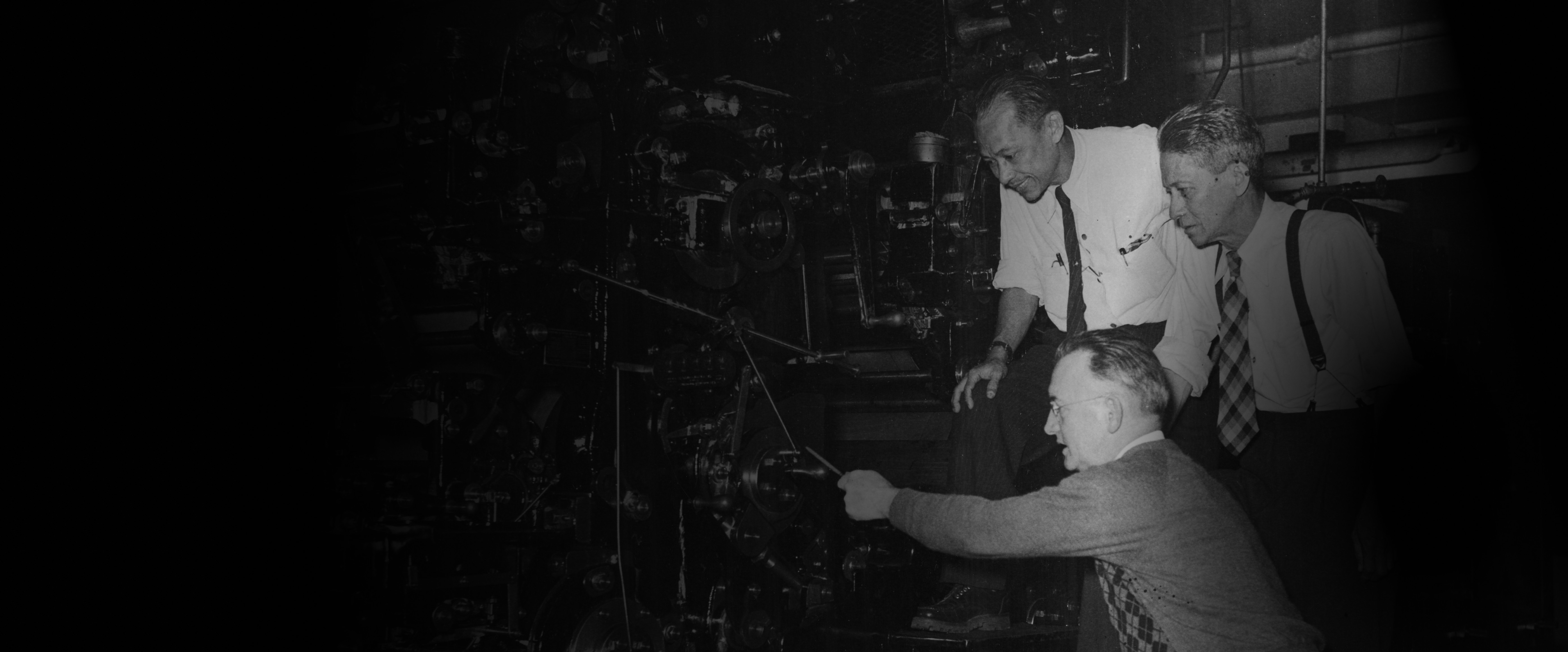

We work side-by-side with your team to uncover how your operations work today—and what’s holding them back. From frontline interviews to full process analysis, we identify the real constraints limiting throughput and visibility.

Designed and deployed on-site, we give you the Industrial AI infrastructure to scale across every facility.

/01

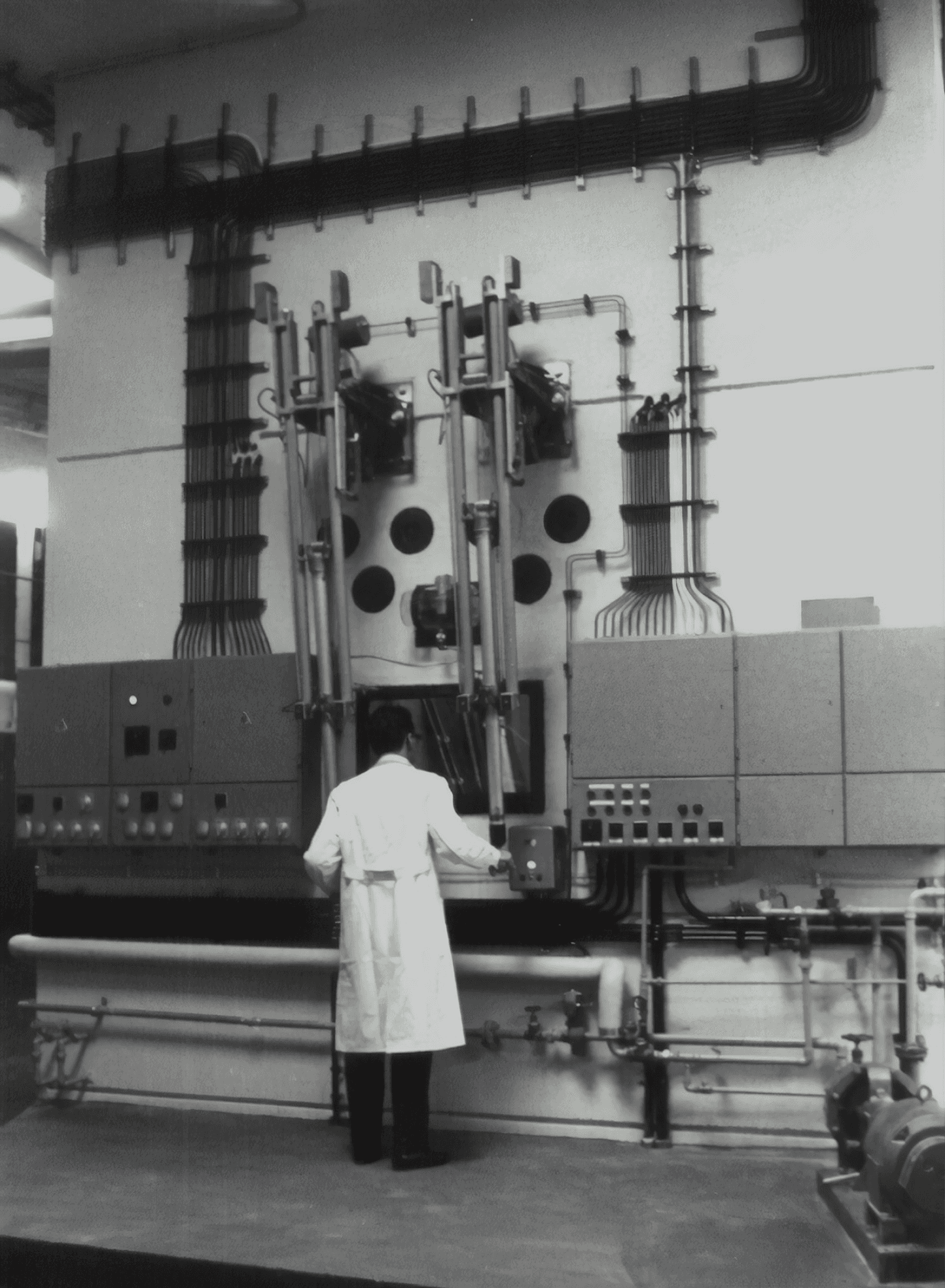

Deploy our FDEs to your factory floor

/02

Learn your process with your team

/03

Define critical outcomes

/04

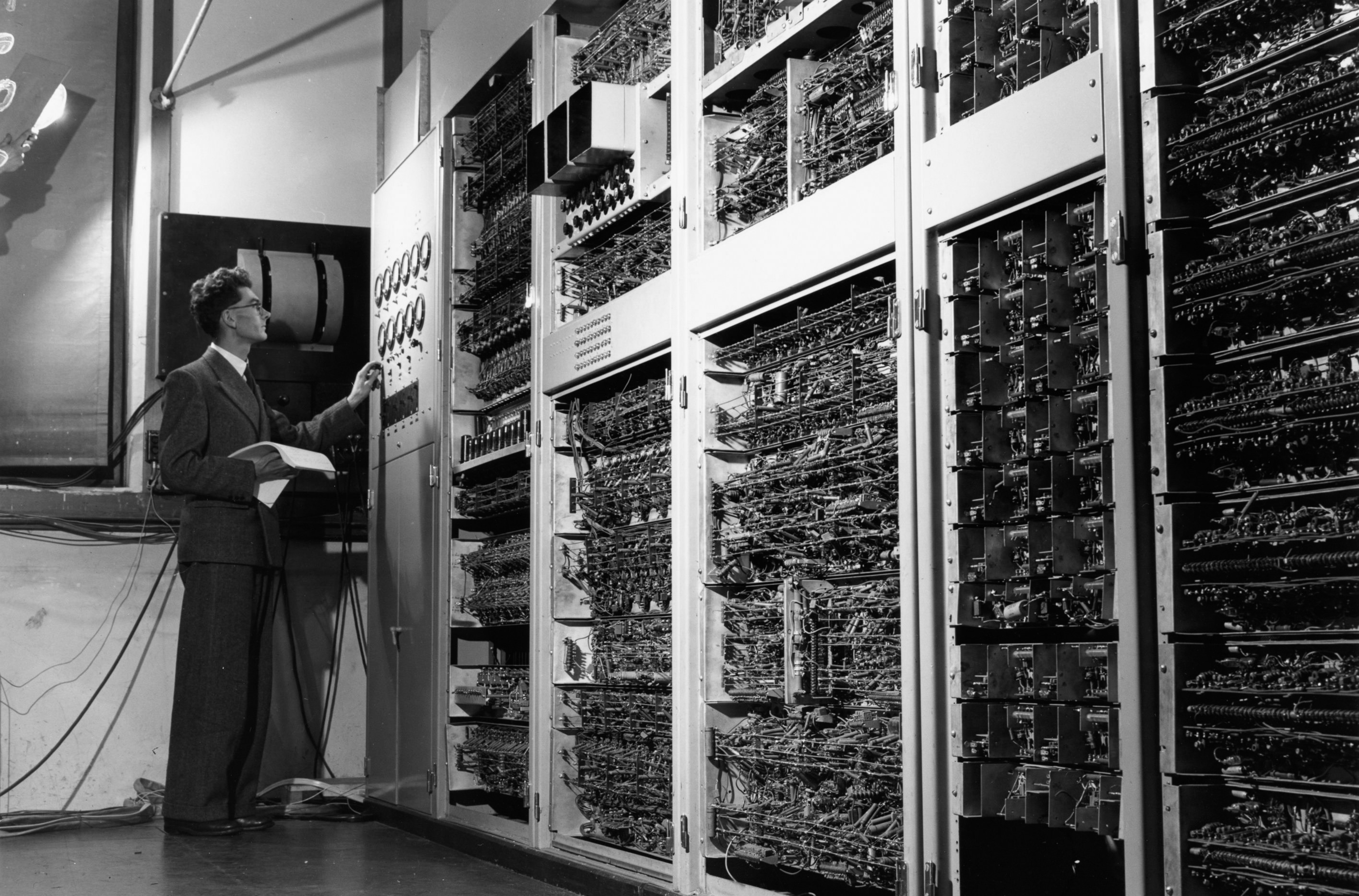

Build applications that drive those outcomes

WHAT WE CAN DO TOGETHER

/LANDSCAPE FORMS

Accelerating automation roadmap by 18 months

/TOP 3 AUTO MANUFACTURER

Decreased hardware-triggered error by 75% on 100+ robot fleet

/SMITH & CO

Real-time CNC monitoring and analytics for high-precision aerospace parts

/LOLL DESIGNS

Real-time CNC monitoring and analytics for increasing sheet yield

JOIN CONDUIT

We’re on a mission to accelerate the next era of American industry.

If you want your code to command robots, drive machinery, and strengthen the industrial backbone this country depends on, this is your place to build.

Head of Robotics

San Francisco, CA

Robotics Software Engineer

San Francisco, CA

Backend Infrastructure Engineer

San Francisco, CA

Head of Operations

San Francisco, CA

Founding Frontend Architect

San Francisco, CA

Founding Design Engineer

San Francisco, CA

Forward Deployed Engineer

San Francisco, CA | Detroit, MI | Hybrid

Backend Engineer

San Francisco, CA

ARTICLES

Industry Report

10/29/25

|

Daniel Pereira

Industrial Robots 2025: America Must Move Faster

The global race for industrial strength and how Conduit ensures the U.S. wins it

AUTOMATION

11/6/25

|

Daniel Pereira

Delay Is Defeat.

Learn how interoperable systems and real-time coordination accelerate production, reduce downtime, and replace slow manual workflows with automation that keeps your factory moving at the speed today demands.

/AUTOMATION

11/17/25

|

Sahil Patel

Factories That Think Fast, Win Fast.

Learn how real-time orchestration converts live data into immediate decisions, enabling factories to automate adjustments, prevent delays, and operate with the speed today’s Industrial AI era demands.

/AUTOMATION

12/9/25

|

Sahil Patel

The Human Layer of Interoperability: Forward Deployed Engineers

See how Conduit’s FDEs bridge technology and execution—deploying automation onsite, training operators in real time, and delivering measurable results that remote consultants and strategy teams can’t match.