/AUTOMATION

12/9/25

|

Sahil Patel

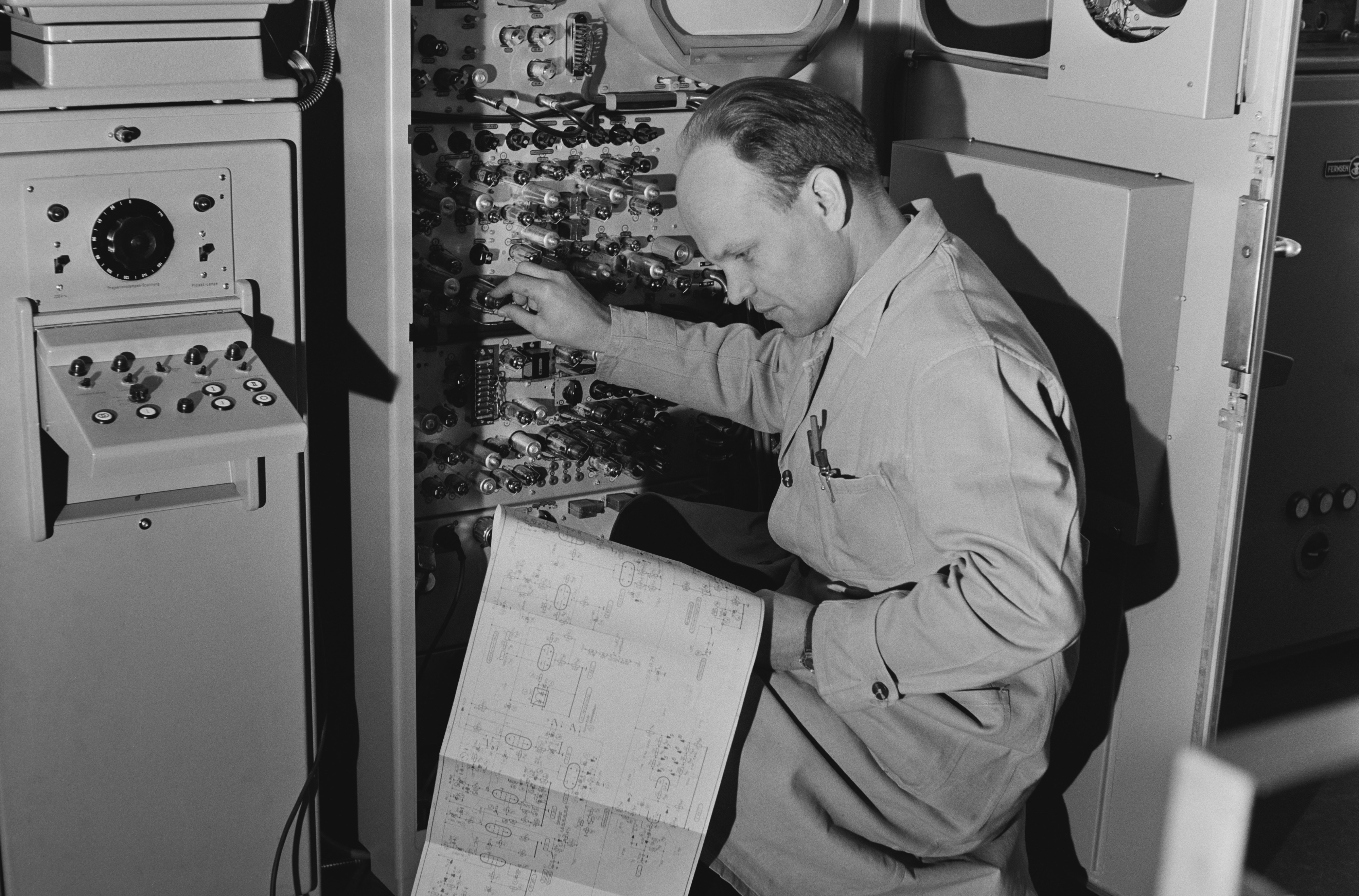

We’re entering a new industrial era powered by Industrial AI, and defined by speed, intelligence, and control.

Manufacturers deploying automation are already cutting downtime, boosting output, and pulling ahead while others wait.

Conduit is built to give American manufacturing this competitive edge as fast as possible. Our Agentic Interoperable Coordination Platform (AICP) turns your live data into action, instantly coordinating robots, machines, and entire factory systems. No drawn-out integrator cycles. No waiting to implement a new plan. Just outcomes visible within weeks.

The Power of Moving First

Global robot installations have doubled in just ten years, reaching 542,000 units in 2024, as factories race to modernize and automate. (International Federation of Robotics 2025)

53% of manufacturers are adopting robots to improve output and quality, leaving slower competitors behind. (ABI Research, 2025)

A 1% increase in robot density drives a 0.8% rise in productivity, with the biggest gains seen for early adopters. (U.S. Department of Commerce, ITA, 2022)

What Manufacturers Can Do Today

Collapse rollout timelines.

Demand automation that deploys in 2 months, not 12. Speed compounds and every week saved builds resilience.

Harness your data.

Use orchestration platforms like Conduit to connect physical and digital systems to make real-time decisions directly from live production data.

Act before it’s perfect.

The factories that lead don’t wait for certainty. They move first, learn faster, and scale smarter.

In this new era, leadership isn’t about size or legacy. It’s about speed and adaptability, which are now available to all manufacturers with Conduit.

Sources:

International Federation of Robotics (2025): Global Robot Demand in Factories Doubles Over 10 Years

ABI Research (2025): 53% of Manufacturers Are Adopting Robots for Quality Improvement

U.S. Department of Commerce, ITA (2022): Robots and the Economy – The Role of Automation in Driving Productivity

More Posts

12/9/25

|

Daniel Pereria

12/9/25

|

Michael McGray

11/17/25

|

Sahil Patel

Navigation

2050 15th St

Detroit, MI

87 MCLEA COURT

SAN FRANCISCO, CA

© 2025 Conduit. All rights reserved.